Informations

Many customers need printing protective films, they want put their LOGO, product information or company information on the surface of protective film that can increase their brand influence. So the printing technology is very important for protective film industry, it should make sure won’t have any printing remain on the surface of products when remove the protective film.

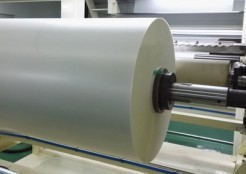

The best way for a perfect printing is double layer composite printing technology, here the layer means film, it means use two films composite one film, one of the film has printed. This way can keep the printing in the middle of the whole film, it will have no any residue of printing. But because it produce with two film together, so normally the thickness will be at least 40um, if the thickness less than 40um, this technology is not suitable.

When the thickness less than 40um, the printing will stick together with glue, if it is high adhesion, sometimes during the application the glue may take away the printed pattern and finally residue on the surface of products. DUTE protective film made a lot of research to solve this problem, we use special printing ink and quality raw material, through the special production process, now we give customers a perfect printing protective film, our printing has many advantages such as bright color, good gloss, excellent printability, good adhesion, no fading etc.

If you want a protective film with perfect printing, please contact us for details.